The Science of Friction and Inclined

Planes

Elsa Lau | UBC PHYS 420C | 2024-25

Ramp

Construction

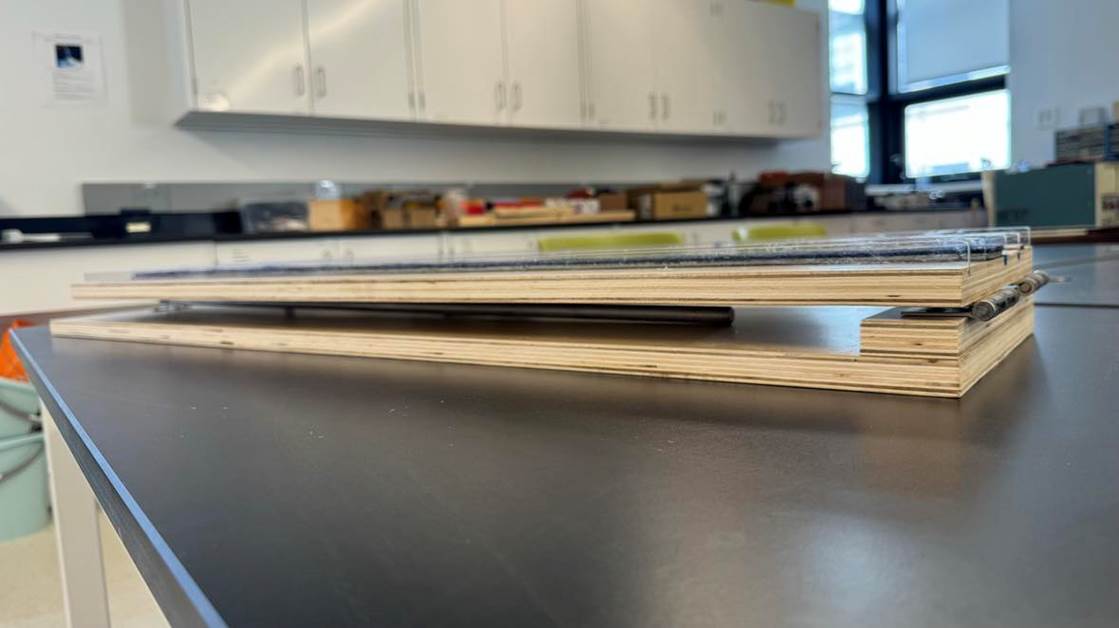

Right: Completed ramp. Left: Completed ramp, collapsed.

Depending

on the number of tracks you want to have and the masses you will be sliding

down your ramp, your dimensions will likely be different, so use this as a

guide only.

Materials

-

Wood for

baseboard: 1000mm x 257mm x 19mm

-

Wood for ramp

base: 900mm x 257mm x 19mm

-

Wood for

anchor: 45mm x 257mm x 19mm

-

Acrylic

dividers: 900mm x 3mm x 18mm (x5)

-

Metal rod:

800mm x 13mm diameter

-

3D printed slider

-

Hinges (x3)

-

Brackets (x2)

-

Screws

-

Butterfly

wing nut

-

Different

surfaces for each track of the ramp

Construction

1.

Once wood is

cut to size, cut grooves approximately 6mm deep in the ramp base

wherever you want your acrylic track dividers to be. You'll want about 2mm of

wiggle room for your mass (e.g. my masses were 51mm wide, so each track was

53mm wide). Also leave some room between the edges of the ramp base and the

outermost dividers (I left 15mm).

2.

Screw the

baseboard, ramp base, anchor, and hinges together as shown.

3.

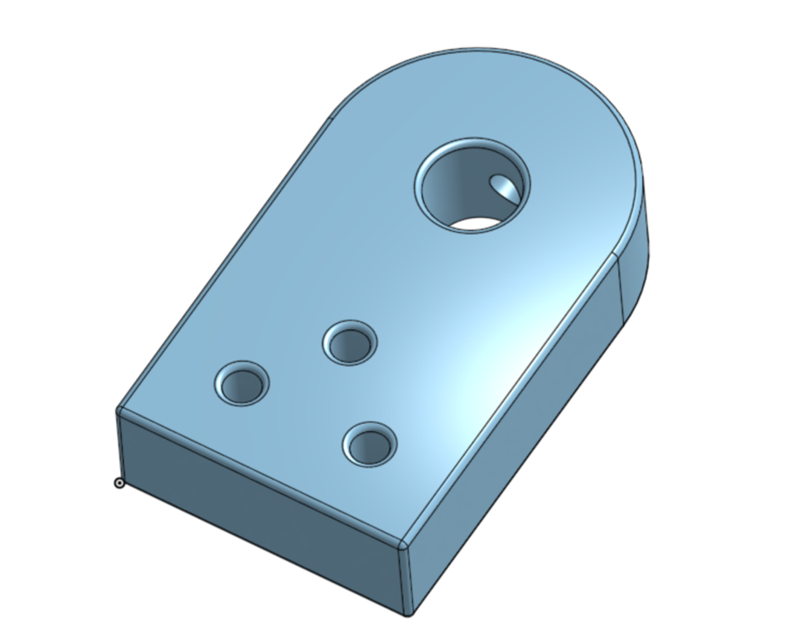

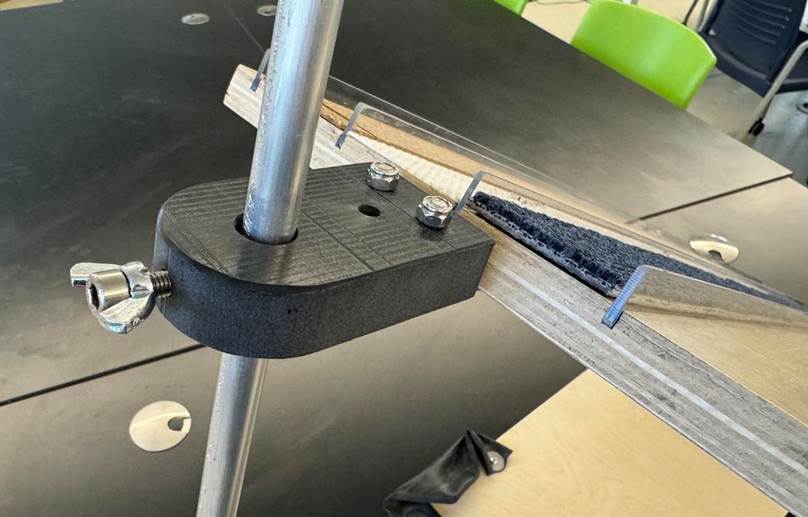

Design a

slider to be 3D printed. It will need to fit the final hinge, the metal rod,

and butterfly wing nut. This is what allows you to adjust the angle of the ramp

and keep it in place. It might look something like this:

4.

Fix the metal

rod in place with the brackets on the baseboard as shown.

5.

Use the final

hinge to attach the slider to the bottom of the ramp base. Make sure it lines

up with the metal rod.

6.

Tape or glue

different materials to the surface of each track. I used cork, carpet, and rubber,

and left the last track as wood. Ensure the track is still flat, or this will

interfere with the demo. Recommended: stick different materials to the surface

of the masses you intend to slide down the ramp as well.